Boosters

|

Model |

C/St |

rpm |

bar ↑ |

bar ↓ |

l/min |

l/min |

kW |

kg |

Dimensions AxBxC, mm |

|---|---|---|---|---|---|---|---|---|---|

| BA10 | 2/1 | 695 |

6 |

40 |

1200 |

875 |

7,5 |

220 |

1210×640×715 |

| 8 | 1485 | 1190 | |||||||

| 10 | 1870 | 1575 | |||||||

| BA15 | 1130 | 6 | 1990 | 1510 | 11,0 | 240 | 1210×660×715 | ||

| 8 | 2450 | 2045 | |||||||

| 10 | 3060 | 2680 | |||||||

| BA20 | 3/1 | 6 | 3040 | 2280 | 15,0 | 310 | 1210×680×715 | ||

| 8 | 3715 | 3070 | |||||||

| 10 | 4590 | 3980 | |||||||

| BA25 | 1270 | 6 | 3425 | 2620 | 18,5 | 330 | 1210×680×715 | ||

| 8 | 4200 | 3535 | |||||||

| 10 | 5160 | 4560 |

Piston booster compressor units (boosters) Remeza are designed to increase the pressure of air, pre-compressed by the compressor of the first stage. They are used wherever high flow rates are required (up to 4500 l / min) at relatively high pressures (up to 40 bar).

Design features

Piston blocks from the world leader Boge (Germany)

Unique solutions such as minimal cylinder clearances ensure high efficiency of piston units. However, the greatest efficiency gains come from increasing the pressure in the existing network, as the energy consumption from the screw compressor / booster combination remains significantly lower than when compared to 2-stage or 3-stage compressors.

Cranks with a large margin of safety. The connecting rod is equipped with a heavy-duty needle bearing on the crankshaft side.

A crankshaft forged from a single piece, dynamically balanced, with a large margin of safety, with roller bearings on both sides.

Ferax combined suction / discharge reed valves with extended service life. Optimized cross-sectional diameters contribute to low resistance to air flow.

The compressor has an additional oil reservoir which extends the service interval. A synthetic oil with a change interval of 2000 working hours is used.

The cooling air flow is directed to the cylinders of the block, which provides effective cooling and allows continuous operation.

Compressors have no restrictions on the duration of the operating cycle due to their design: the piston speed is about 3 m / s (for comparison, diesel engines operate at a speed of 7-15 m / s), reduces the heat generation of components and thereby reduces loads and wear, which ensures low operating costs, cost savings and long service life.

Maximum flexibility in setting primary and final pressures

The boosters can be easily combined with screw compressors with final pressures from 6 to 10 bar (g). The final pressure can be changed at any time as needed to adapt to the user's production requirements.

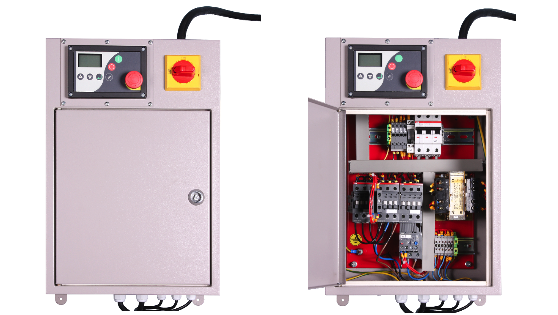

Control system

Airmaster P1 controller in BA series compressor units:

- Operating time counter.

- Output pressure indication. The ability for the consumer to programmatically set the pressure limits in the permissible range.

- Overload monitoring of the motor. Automatic shutdown of the compressor unit in case of accidents with indication of alarm messages.

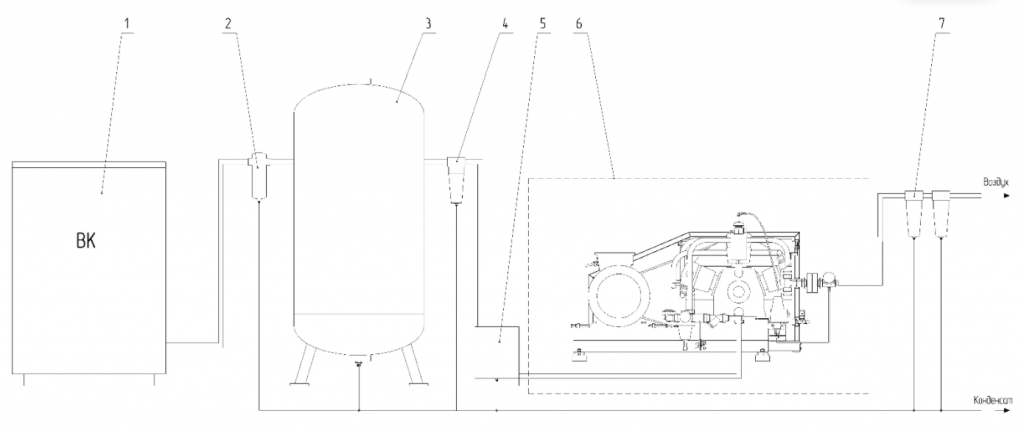

Scheme of a complete compressor station

2.Water-oil separator

3.Air tank

5.Refrigerant air dryer

6.Booster

7.Filters with additional filtration 0,01 mkm

Application area

- Food industry.

- Car manufacturing.

- Blowing PET bottles.